Reports

|

|

| Trimmer on the back | Over all view |

I fixed a 15LA OS engine with 4 steel cap screws of M3x55 through brass spacers of 40mm (1.6") long, similarly a simple tachometer with an angled plate on a steel base. It is about 10 mm ( 0.4" ) distance between a blade and a photoreflector of the tachometer. A trimmer can adjust from the back of the wiring board. I clumped a 80 mL ( 4.9 in3 ) fuel tank with a folded sheet metal bracket, and attched to the base. The 3.2mm ( 0.13" ) thick base weighs 2.2kg ( 4.9lb ). I attached 4 rubber feet under the base to relax vibration of the engine.

The base was a work sample to design a machine for my customer. The customer gave me the disk, who works a 600 ton press blanking machine that ejects a pair of the sample per 1.5 second. I did basic and system design of an elevating automatic stacker which loads 660kgf ( 1450lb ).

DSO

|

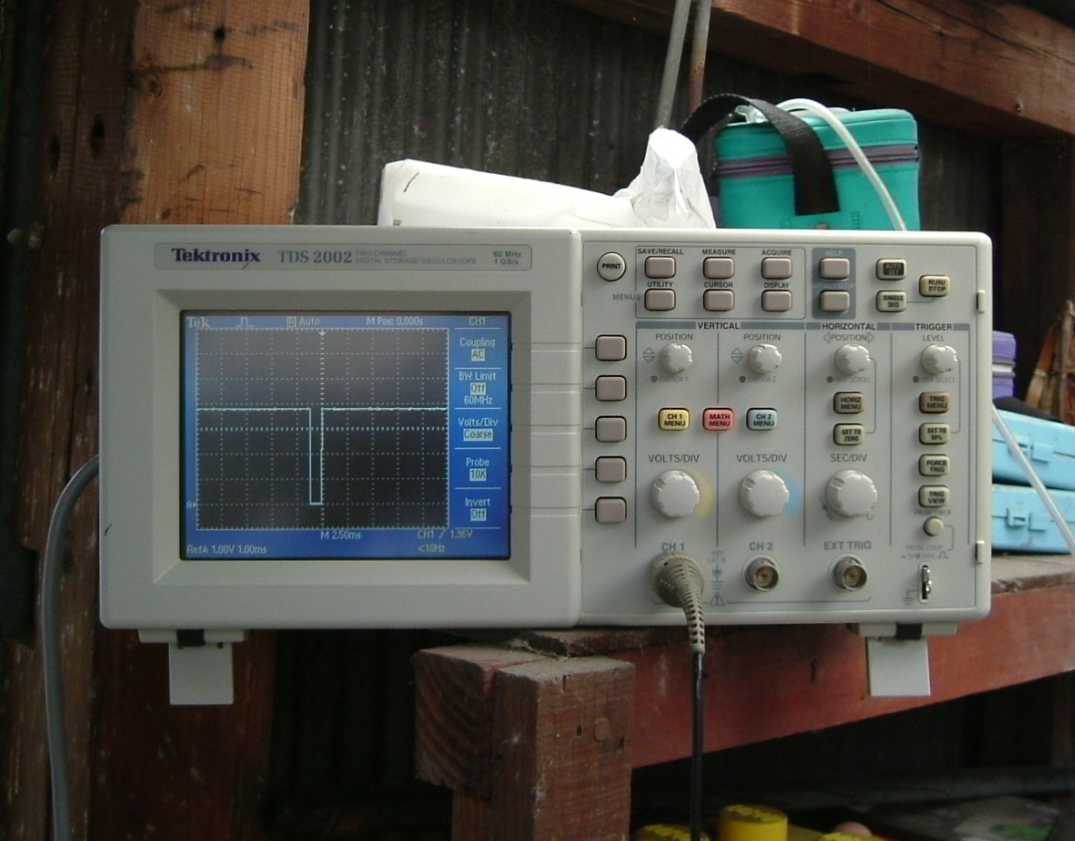

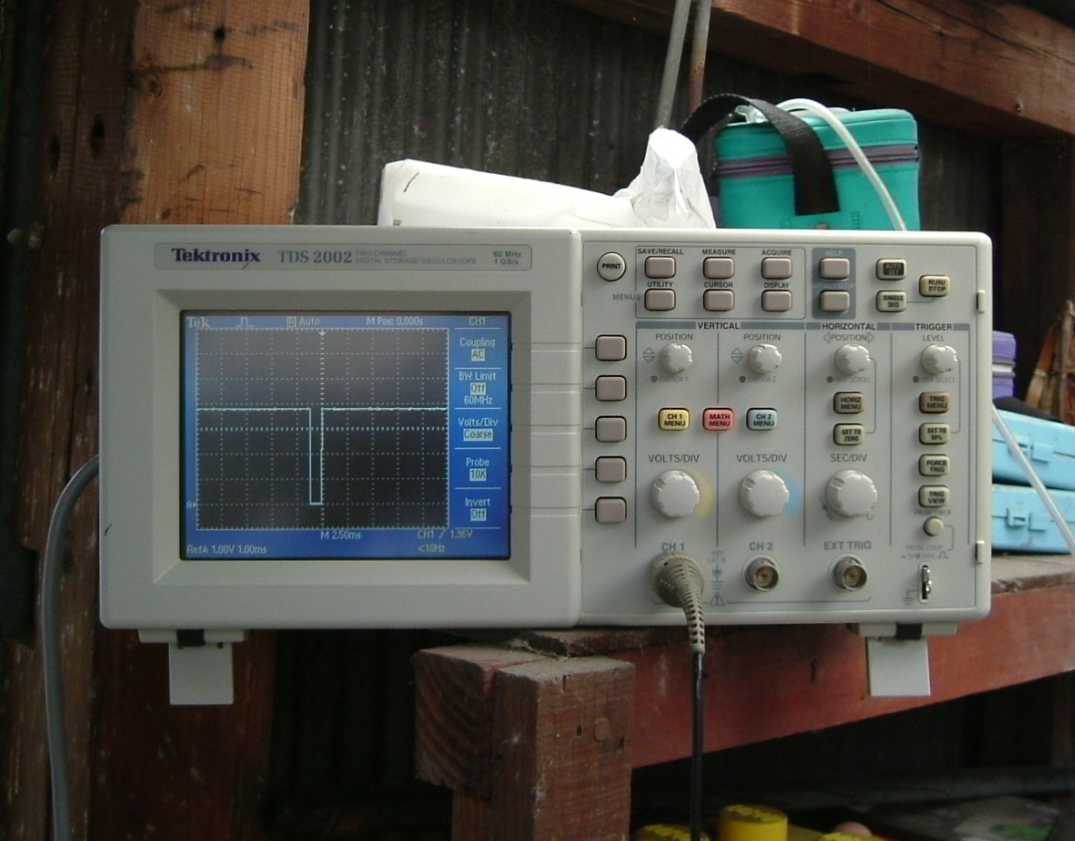

I use a syringe of 50ml (3 in3) with a measuring scale to fill oil. I connected a small diamter tube compared with usual fuel tube to decrease dead volume. The dead volume is 1/4. I attached a fuel cock and a wire stopper which fixes throttle link. I used a 8x4 prop ( IM ) and fuel of Aerostar 15 by COSMO , and plug heater by PWM ( Pulse Width Modulation ). Temperature was about 20°C ( 68°F ). A DSO ( Digital Storage Oscilloscope ) detects pulses of the tachometer and measures the frequency. The photo shows a measured pulse of the tachometer. The result as follows. The tachometer can measure running speed of a glow engine sucessfully. The engine can rotate at high speed of 13500 rpm and low speed of 5400 rpm. But the bench does not sit still because of severe vibration at max speed. How about marginal low speed?

Biwa Lake JAPAN aboutMe

© 2007-2011 Enoki Sensor All Rights Reserved

|