Reports

|  |

| Conventional | Improved |

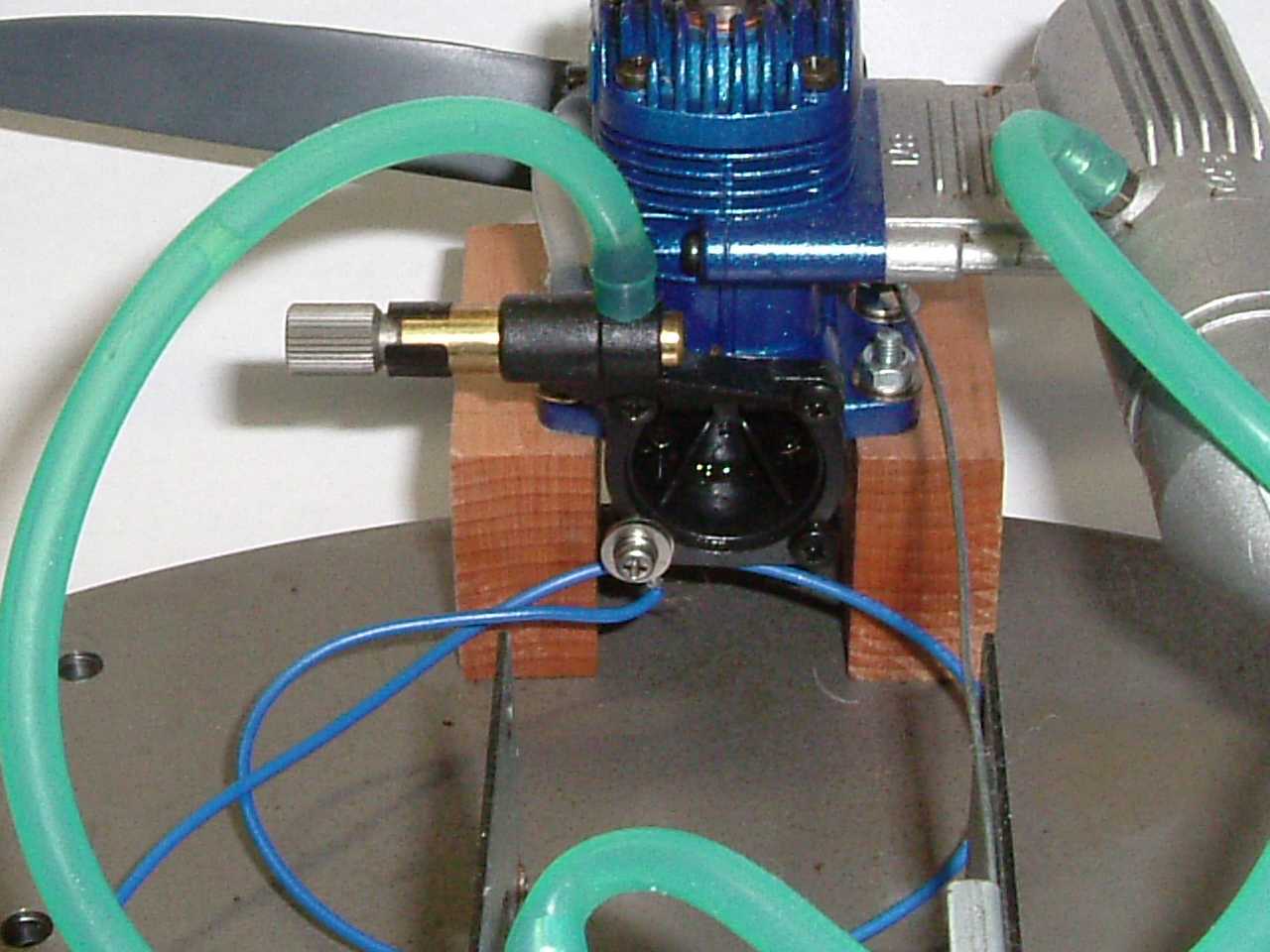

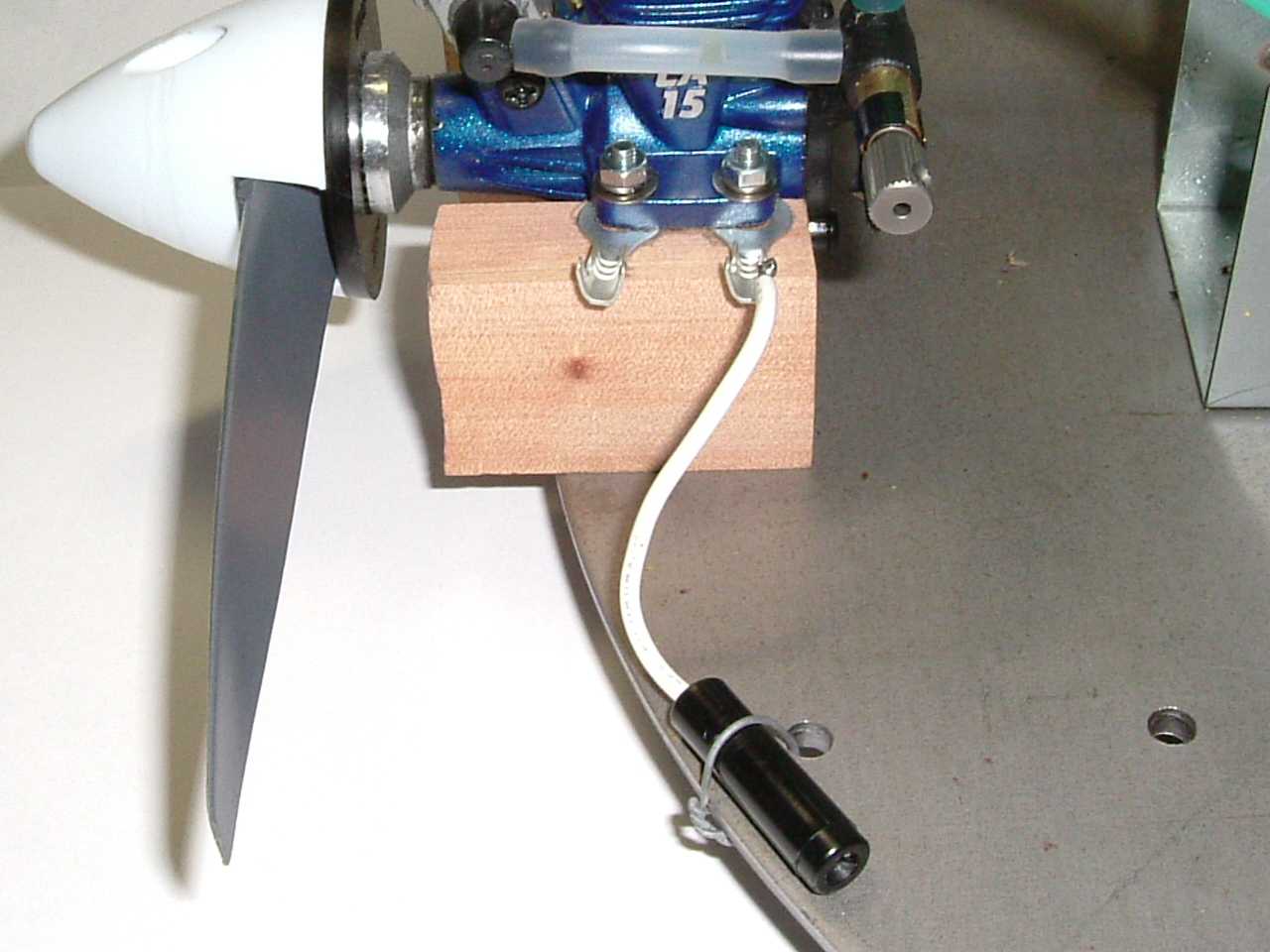

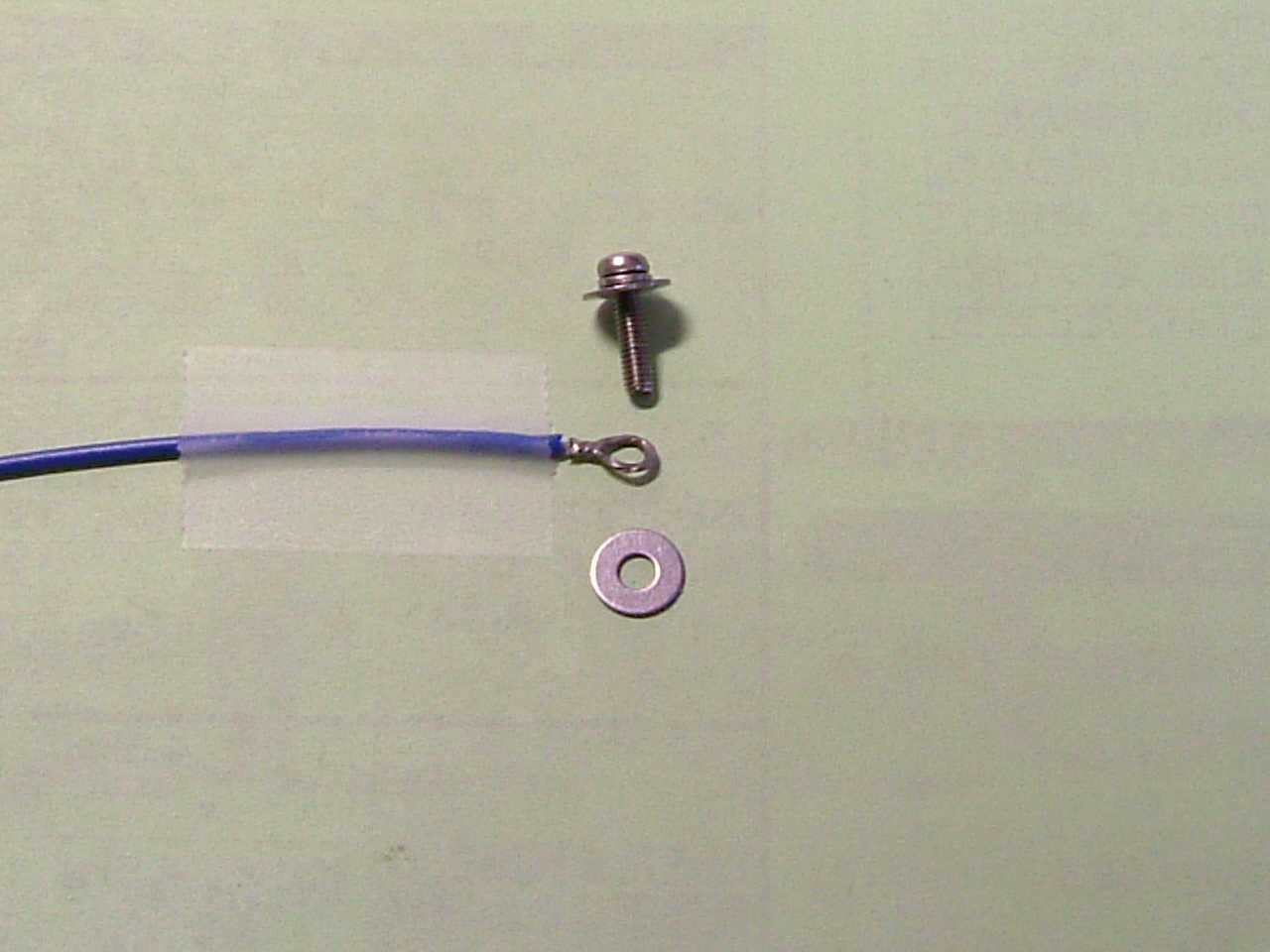

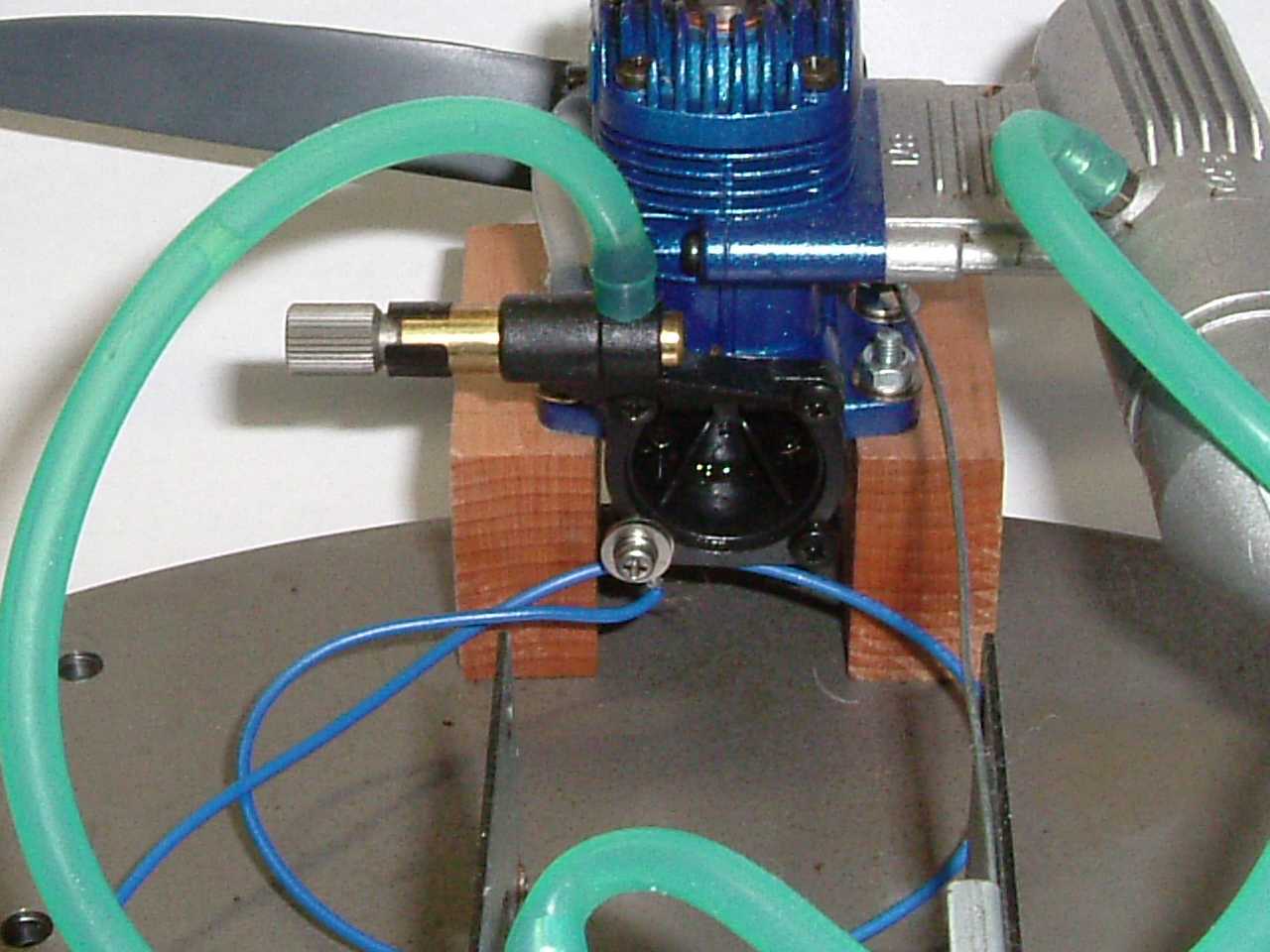

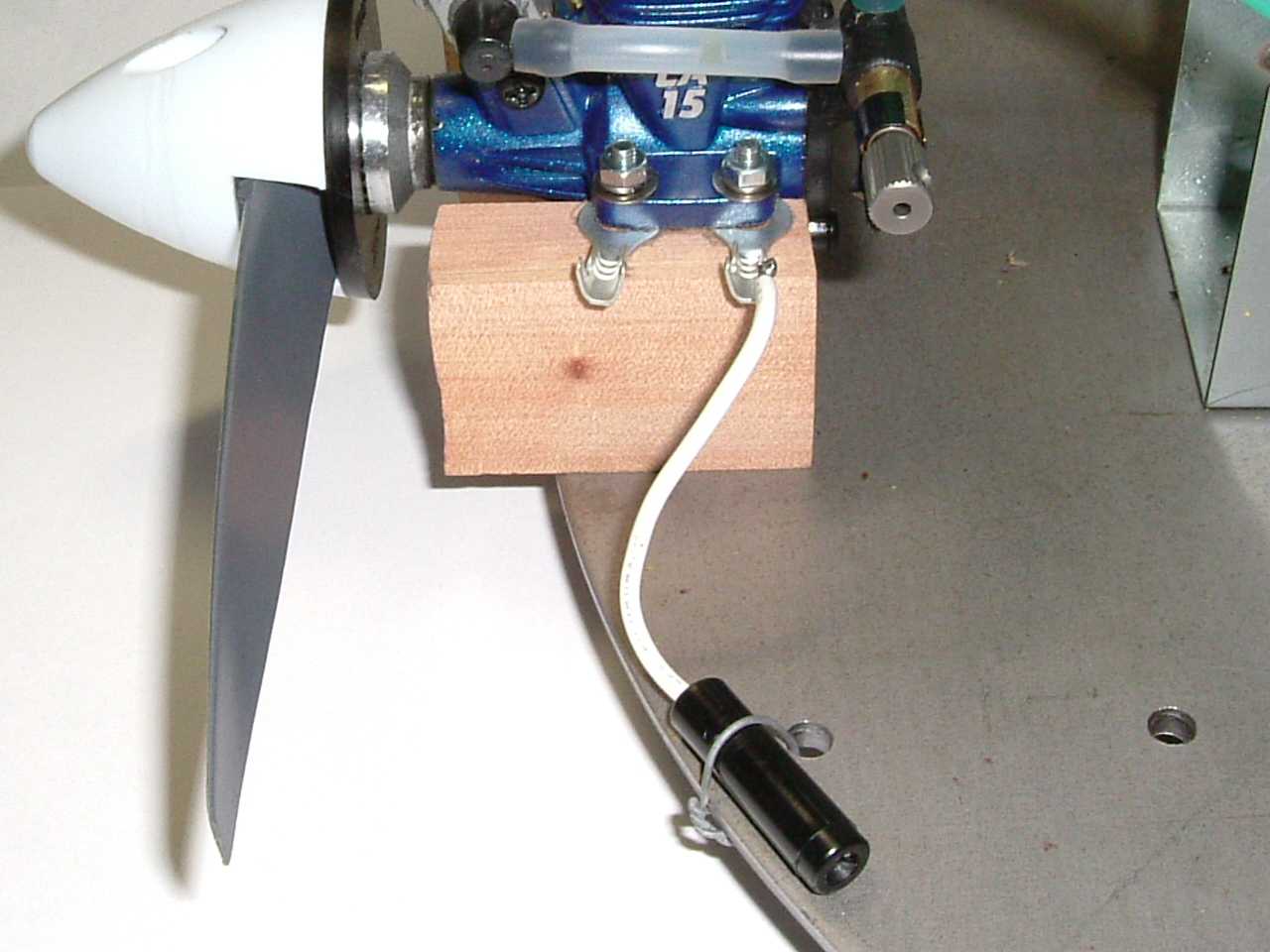

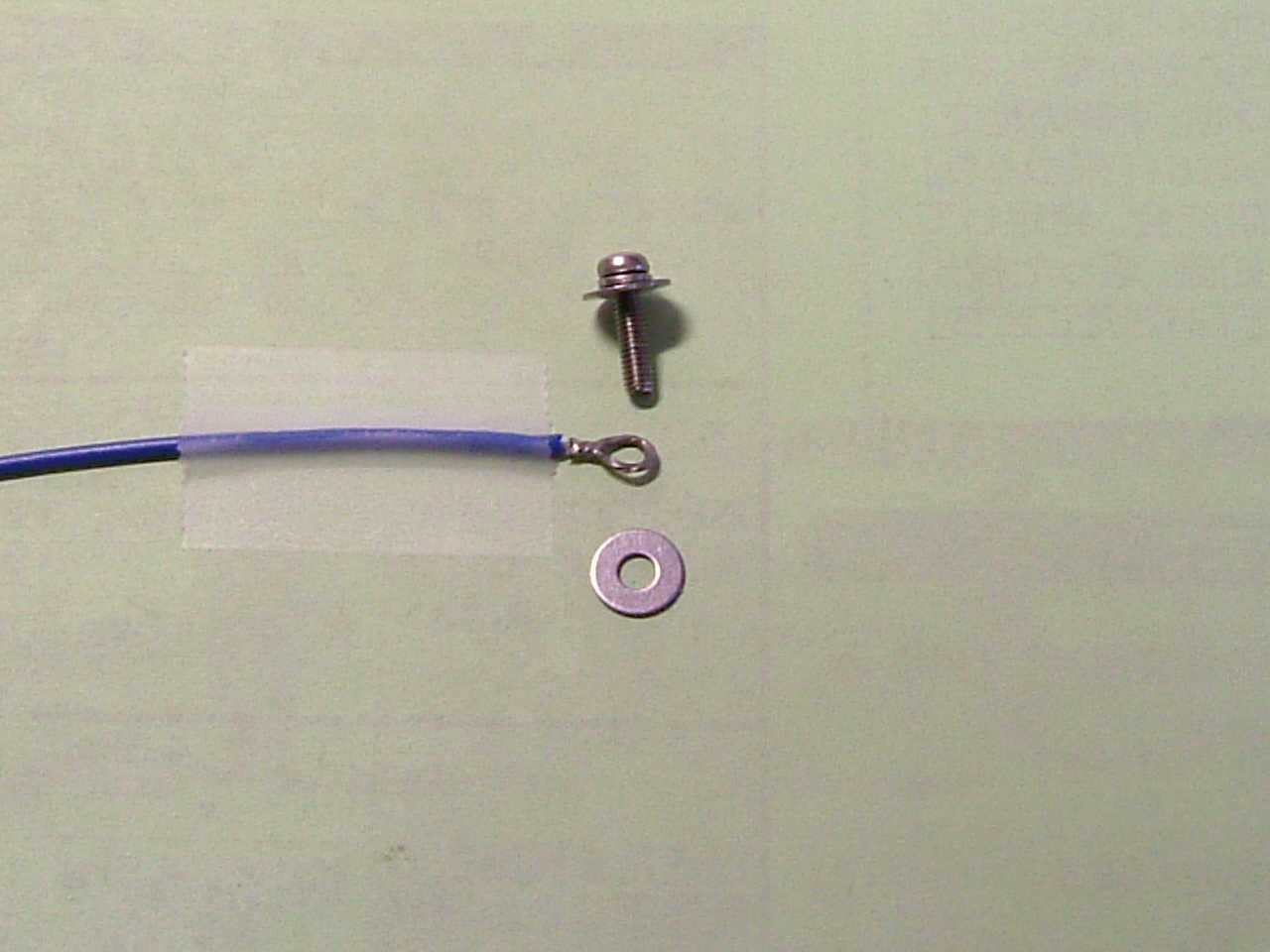

I was surprised at seeing bubbles between the black plastic cover plate and the crank case, when the engine was running. I judged that the termination was not good electrically. See the photo "Side view". I changed brass pillars for blocks of woods to isolate vibration of the engine. I attached a terminal of internal diameter of 5.3mm (0.21") and 0.6mm (24mil) thick under the seat of the engine. I also attached the same 3 terminals to maintain level. How stupid! What merit of insulating blue coat does the engine have? The white wire is 0.5SQ (AWG20) and 6.5cm long. The conventional termination was M3 screw with spring washer and wire 0.2SQ (AWG24).

|  |

| Conventional | Side view |

Biwa Lake JAPAN aboutMe

© 2008-2011 Enoki Sensor All Rights Reserved

|